The Benefits of Metal Laser Cutting: A Comprehensive Guide

Laser cutting is one of the most popular metal fabrication techniques. Its precision and speed make it an ideal choice for many applications. A laser cutter uses a beam of electricity to cut, engrave and mark the material it’s working on. Unlike other thermal cutting methods, the heat-affected zone is small and doesn’t cause warping or distortion.

Precision

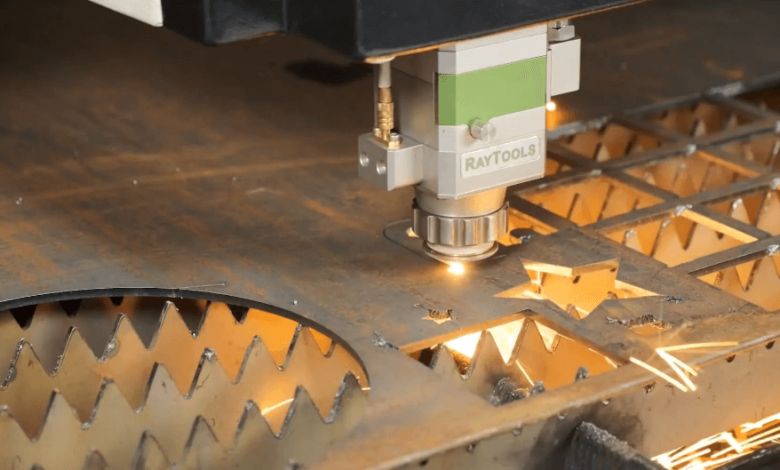

Metal laser Columbus, OH cutting is a precise process that delivers accurate cuts. It can also cut materials that are difficult to cut using traditional or mechanical methods. This makes it an ideal choice for fabricating products and prototypes. When cutting metal, the laser beam heats and vaporizes the material. An auxiliary gas, such as nitrogen or argon, blows away the molten debris. This helps keep the material’s temperature consistent, resulting in clean and precise cuts. New nozzle technology can even improve the delivery of this auxiliary gas to increase efficiency and productivity. The precision of laser cutting depends on the machine’s settings, the type of material, and its properties. For example, woods with different resin counts require different laser machine settings. Choosing the wrong setting can degrade the quality of the cuts and damage the workpiece. A specialist knows the correct settings to use for different materials. In addition, they follow proper laser safety protocols to prevent accidents and hazards.

Speed

If the correct settings are used, laser cutting can cut thicker metals than other processes. A skilled operator can optimize the power, speed, and nozzle alignment and assist gas to achieve great results. As a noncontact process, laser cutting eliminates the need for fixturing of materials, saving time and money on setup. This can also reduce potential machine downtime and operator error related to the setup. Laser cutting can produce smaller holes with a shorter cycle time than manual or mechanical, allowing for faster production. This can be particularly useful for prototyping. When paired with a suitable design file, laser cutting can help you bring your ideas to life faster, so you can get them into the market sooner. This is another reason why design for manufacturability (DFM) is essential and the need to create accurate prototypes.

Efficiency

Laser cutting is one of the most efficient fabrication processes for sheet metal. This is because it cuts the material using thermal energy without any pressure or shear and therefore doesn’t induce distortion. The heat-affected zone is also relatively small, allowing the laser to cut complex shapes and patterns without altering the part’s tolerance. However, to get the most efficiency out of laser cutting, it is necessary to know how to prepare and operate the equipment properly. For example, the nozzle should be in good condition to prevent deformation or clogging. It’s also essential to find the right power, speed, and laser focus combinations for each material through test runs. This ensures the accuracy and reliability of the process. This, along with its versatility and efficiency, makes metal laser cutting an excellent choice for prototyping and production.

Safety

While laser cutting can be used on various materials, it has risks. For example, the laser emits a beam that heats the material to the point of melting or vaporizing it. In addition, when cut, certain materials produce harmful fumes, such as airborne benzene, toluene, hydrochloric acid, and isocyanates. These fumes can be deadly if inhaled. Therefore, metal fabrication shops must ensure the proper exhausting system is in place for their laser cutter machines.

Additionally, it is essential for fabricators always to read the machine’s manual. This will help them understand the equipment’s capabilities and what it can and cannot do, such as whether cutting through a specific metal thickness is safe. It also informs them of any safety precautions that should be taken, such as wearing eye protection or knowing where to find the fire extinguisher in case an emergency occurs. By following these simple guidelines, metalworkers can reduce their risk of accidents and produce flawless results.